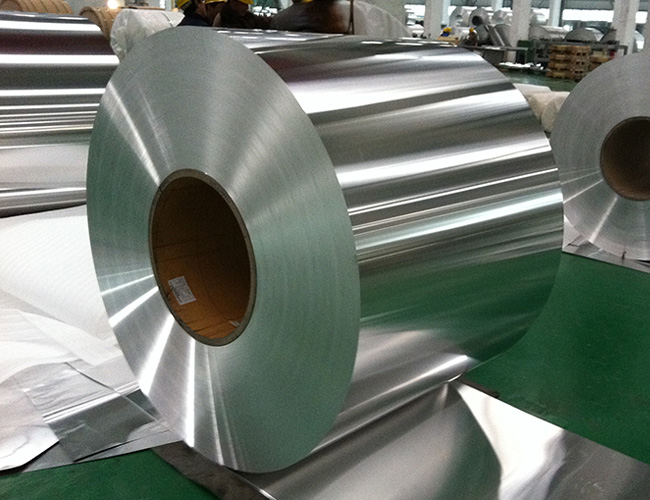

Aluminum Foil Coil

2026-02-09 10:59:14

Brief Introduction

Our aluminum foil coil is engineered for consistent gauge control, clean surface quality, and reliable forming performance across packaging, insulation, HVAC, and industrial lamination applications. With flexible alloy/temper options and custom slitting, it helps you reduce scrap, improve line efficiency, and maintain stable end-product quality.

Whether you need a general-purpose aluminium coil solution or a tightly controlled foil coil for converting, we supply production-ready material with export-standard packaging and traceable quality documentation.

Key Parameters (Typical, Customizable)

Final specifications are produced to your confirmed requirements and application.

- Material: Aluminum foil coil (slit coil / jumbo roll available)

- Alloy options: 1xxx / 3xxx / 8xxx series (commonly used for foil and insulation fields)

- Temper: O (soft) / H14 / H16 / H18 / H22 / H24 (as required)

- Thickness range: 0.006 mm to 0.200 mm (typical converting range)

- Width: 20 mm to 1600 mm (custom slitting supported)

- Inner diameter (ID): 76 mm / 152 mm / 300 mm (or as requested)

- Outer diameter (OD): Customized by weight and handling limits

- Surface: Bright, matte, one-side bright, both-side bright; clean and oil-controlled

- Core: Paper core or aluminum core

- Standards: ASTM / EN / JIS (available upon request)

- Processing services: Slitting, rewinding, edge trimming, embossing/lamination compatibility support

Purpose and Applications

Aluminum foil coil is valued for its barrier performance, thermal reflectivity, formability, and corrosion resistance. Typical uses include:

- Thermal insulation and jacketing: HVAC duct wrap, pipe insulation outer layer, reflective insulation systems

- Industrial lamination: Foil-faced panels, vapor barriers, multi-layer composites (PE/PET/paper)

- Packaging and converting: Food and pharmaceutical packaging structures (based on required grades and compliance)

- Electrical and shielding: Cable wrap, EMI shielding laminates

- Construction and building materials: Roofing underlayment facings, moisture control layers

For insulation-focused projects, you can also match this product with our Aluminum Jacketing Coil to cover different thickness and forming requirements.

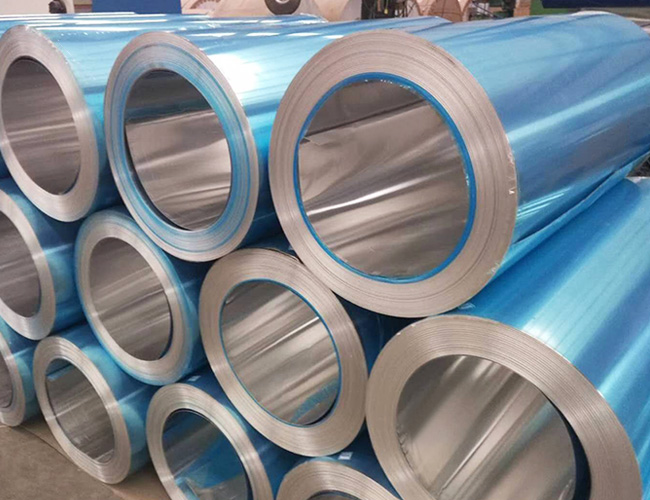

Packaging (Export-Safe)

We design packaging to protect coil edges and surfaces during long-distance transport and repeated handling.

- Inner protection: Anti-scratch film or interleaving paper (optional)

- Moisture protection: VCI / desiccant + sealed plastic wrap

- Outer protection: Corrugated paper + steel strip reinforcement

- Palleting: Fumigation-free wooden pallet or customized skid

- Loading: Eye-to-wall or eye-to-sky as requested

- Labeling: Alloy, temper, thickness, width, net/gross weight, batch number, and traceability info

Advantages (Why Buyers Choose This Aluminum Foil Coil)

- Stable thickness & flatness: Better yield for slitting, rewinding, and laminating lines

- Clean surface quality: Reduced pinholes, fewer coating/lamination defects

- Consistent mechanical properties: Predictable forming, wrapping, and bending performance

- Custom slitting & fast matching: Width/ID/OD tailored to your equipment and process

- Cost-effective logistics: Coil weight and packaging optimized for container utilization

- Quality control support: Mill test certificate (MTC) and inspection data available

FAQ

Q1: What alloy and temper should I choose for my application?

For lamination and converting, softer tempers like O are often preferred for better formability, while H14/H16/H18 are common when higher stiffness is required. Share your end use and process steps (lamination, embossing, forming), and we will recommend the best match.

Q2: Can you supply slit coils in small widths?

Yes. We support custom slitting for narrow widths and can recommend tolerances based on your rewinding and converting equipment.

Q3: Is the foil coil suitable for insulation jacketing?

Yes. For insulation outer layers, coil selection typically depends on thickness, temper, and corrosion environment. If you need a jacketing-focused option, consider the dedicated Aluminum Jacketing Coil as well.

Q4: What are the common defects to control for foil coils?

Typical concerns include surface scratches, oil level, pinholes, edge burr, and thickness variation. We can align inspection criteria to your standard and provide inspection records.

Q5: What information do you need for a fast quotation?

Please provide: alloy, temper, thickness, width, ID, target coil weight/OD, surface requirement, quantity, and application. If you have a drawing or previous spec sheet, even better.

Request a Quote

Send your required thickness, width, temper, and application, and we will recommend the best aluminum foil coil configuration, packaging method, and delivery plan for your production line.