Aluminum Channel Letter Coil

2026-02-09 10:59:11

Brief Introduction

Build sharper, longer-lasting signage with aluminum channel letter coil designed for professional channel letter returns. This coil delivers consistent thickness, smooth coating, and reliable bend performance to help you form clean edges, tight radii, and crisp letter walls with fewer defects. Whether you run a sign shop, fabricator line, or OEM production, this coil is made to keep throughput high and rework low.

Key Parameters (Typical Options)

Note: Custom specifications are available based on your letter bender and project requirements.

- Material: Aluminum alloy (commonly AA1100/AA3003 class options)

- Temper: Soft to medium tempers for stable forming (e.g., O/H14, depending on spec)

- Thickness: Typically 0.040–0.080 mm (customizable)

- Width: Commonly 30–200 mm (customizable for different return heights)

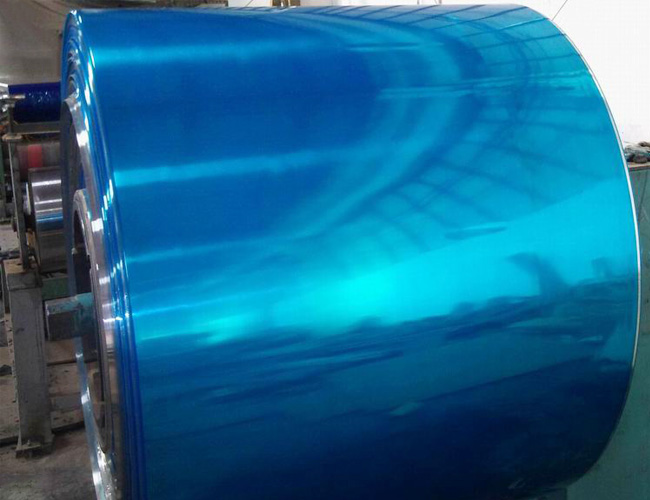

- Coating: Painted / pre-finished (single side or double side)

- Color: Standard colors + custom matching available

- Surface finish: Smooth, uniform, low orange peel

- Core/ID: Standard coil ID options to fit feeding systems

- Compatibility: Manual and automatic channel letter bending machines

If you're comparing raw material choices, our aluminum coil stock options can also be configured for sign-making applications.

Purpose and Applications

This channel letter return coil is used to form the side walls (returns) of:

- Front-lit channel letters

- Halo-lit (reverse) channel letters

- Push-through and cabinet signage

- Logo outlines, trims, and custom-shaped returns

- Indoor and outdoor commercial signage for storefronts, malls, and wayfinding

Its stable forming behavior supports consistent results across short custom jobs and long production runs.

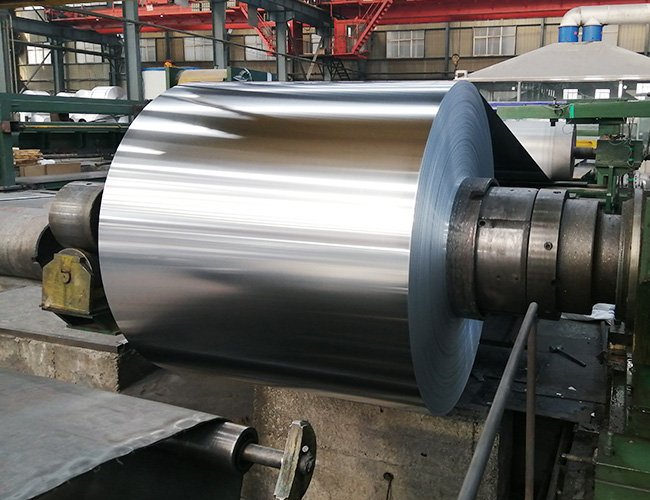

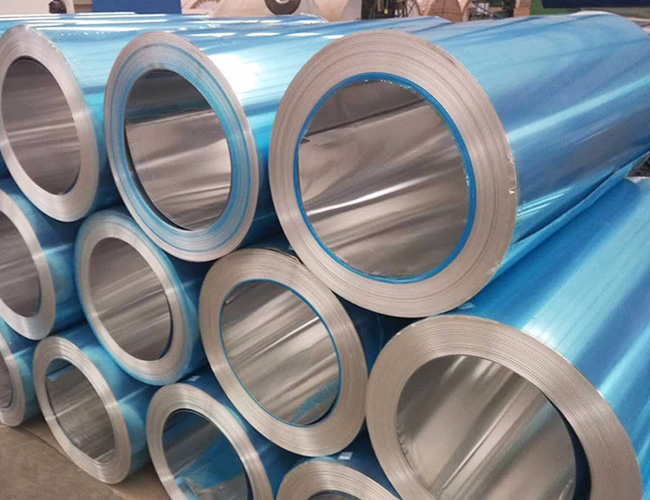

Packaging

Every roll is protected to reduce transit damage and keep the surface clean for production:

- Inner protection: Film and/or paper interleaf to prevent scratching

- Edge protection: Edge guards to prevent dents and coating chips

- Outer wrap: Moisture-resistant wrapping

- Export packing: Strong carton/pallet or wooden crate options

- Labeling: Alloy, temper, thickness, width, color, batch traceability

Advantages (Why Sign Makers Choose This Coil)

1) Clean Bending, Fewer Surface Defects

Optimized temper and coating flexibility help reduce cracking, flaking, and edge whitening during tight-radius bending.

2) Strong Weather and Corrosion Resistance

Aluminum naturally resists corrosion, while the pre-finished coating helps maintain color and appearance outdoors.

3) Consistent Thickness = Consistent Returns

Uniform gauge supports predictable forming and more stable letter walls, improving final fit and appearance.

4) Excellent Bonding and Finishing Compatibility

Works well with common adhesives, tapes, and mechanical fastening used in channel letter assembly.

5) Custom Colors for Brand Matching

Choose standard colors or match custom palettes to keep signage aligned with brand guidelines.

For specific alloy selection (especially for high-forming needs), you can also reference our 1100 Aluminum Coil for excellent ductility in forming applications.

FAQ

Q1: What thickness should I use for channel letter returns?

Most sign makers choose a range around 0.040–0.080 mm depending on return height, letter size, and whether the job prioritizes flexibility or rigidity. We can recommend a spec based on your bender model and typical letter sizes.

Q2: Will the coating crack when bending tight corners?

Our coil is designed for signage forming, with coating flexibility tuned for bending. Proper setup (roller pressure, feed alignment, and radius settings) further reduces the risk of cracking.

Q3: Can I order custom widths and colors?

Yes. Custom width (to match return height) and custom color matching are available. Share your target width, thickness, color standard (RAL/Pantone), and estimated monthly usage.

Q4: Is this coil compatible with automatic channel letter benders?

Yes. Standard coil ID/OD configurations can be supplied to fit common feeding systems. Tell us your machine requirements to confirm.

Q5: How is the coil protected during shipping?

We use protective wrapping, edge guards, and sturdy export packaging to minimize dents, scratches, and moisture exposure.

Ready to Quote

Send your required thickness, width, color, coil ID, and application (front-lit/halo-lit). We'll recommend the best aluminum channel letter coil spec to improve forming quality and reduce waste in production.