Aluminium Circle Price Per Kg

2026-02-03 09:07:58

Brief Introduction

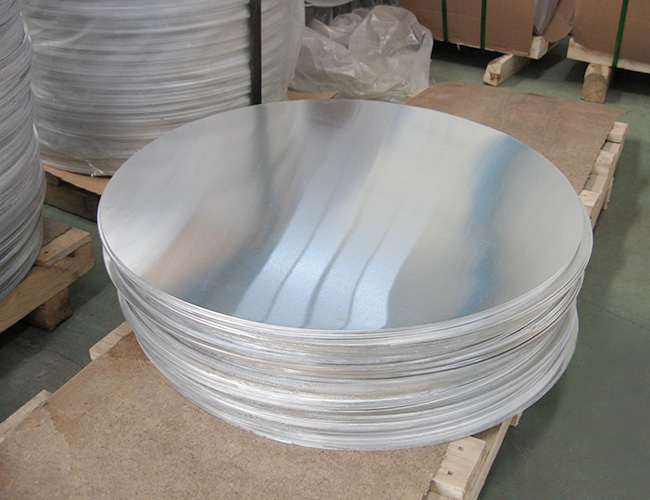

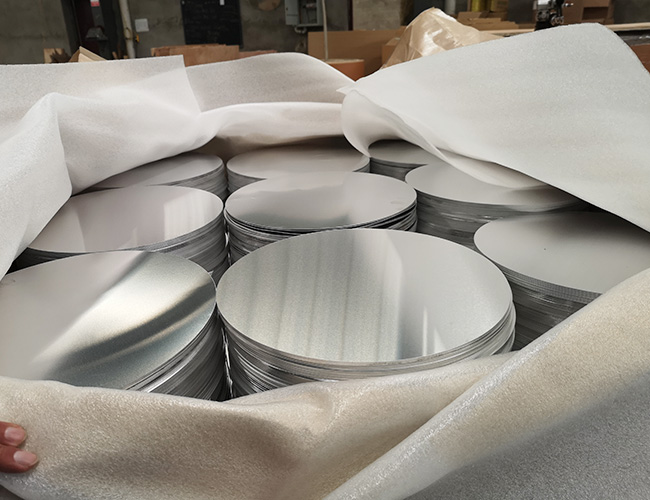

If you are comparing aluminium circle price per kg, consistency in alloy, thickness tolerance, and surface quality matters as much as the number. Our aluminium circles (also called aluminum discs) are produced from quality coil, precision blanked, and packaged for safe transport, helping you reduce waste, improve forming yield, and keep your production stable.

Whether you need circles for cookware, lighting reflectors, stamping, or deep drawing, we offer multiple alloys and tempers with stable performance for mass production.

Key Parameters (Specifications)

Product name: Aluminium Circle / Aluminum Disc

Material (Alloy Options)

- 1050: High purity, excellent forming, great for cookware and general forming

- 1100: Very good corrosion resistance and workability, widely used

- 3003: Better strength than 1xxx series, good for deeper drawing and durability

- 8011: Common for cookware applications, stable forming and cost-effective

Temper Options

- O (Annealed)

- H12 / H14 (Semi-hard options, depending on application)

Size Range (Customizable)

- Thickness: 0.3 mm to 6.0 mm (custom support)

- Diameter: 50 mm to 1200 mm (custom support)

- Tolerance: Available upon request based on your drawing and application

Surface & Quality

- Mill finish / Clean surface

- Smooth edges, low burr

- Suitable for anodizing, coating, and further processing

Standards & Inspection

- Material certificate available (heat/lot traceability)

- Dimensional inspection and surface checks before packing

Aluminium Circle Price Per Kg: What Affects Your Final Cost?

The aluminium circle price per kg is usually influenced by:

- Aluminum ingot price (market-linked)

- Alloy and temper (e.g., 1050 vs 3003)

- Thickness/diameter and tolerance requirements

- Surface quality and edge quality (for deep drawing and anodizing)

- Order quantity and packaging requirements

Tip for buyers: If your process is deep drawing or spinning, choosing the correct alloy/temper can reduce cracking and scrap, lowering your true per-piece cost even if the per-kg price is slightly higher.

Main Purposes (Applications)

Our aluminium circles are widely used in:

- Cookware: pots, pans, pressure cooker bodies, lids

- Lighting: lamp shades, reflectors, LED housings

- Electrical: capacitor shells, covers

- Industrial forming: stamping parts, spinning, deep drawn components

- Signage & decorative parts: anodized discs, nameplates

Packaging (Export-Safe)

To protect surface finish and prevent deformation during shipping, we use reliable, production-friendly packing:

- Plastic film + moisture barrier (as needed)

- Paper interleaf (optional for surface protection)

- Strong wooden pallet or wooden case

- Steel strap reinforcement

- Clear labels: alloy, temper, size, net/gross weight, batch number

Packaging can be customized for container loading, warehouse storage, or automated line feeding.

Advantages (Why Buyers Choose Our Aluminium Circles)

- Stable forming performance: consistent metallurgy for stamping, spinning, and deep drawing

- Clean surface quality: helps reduce polishing and rejects

- Accurate dimensions: controlled thickness and diameter for repeatable production

- Smooth edges, low burr: safer handling and better forming

- Multiple alloys in stock: 1050/1100/3003/8011 available

- Flexible supply: supports trial orders and long-term contracts

- Fast quotation: share your required alloy, temper, thickness, diameter, and destination to receive a quick price per kg

FAQ

1) What is the current aluminium circle price per kg?

Price per kg depends on alloy (1050/1100/3003/8011), temper, size, tolerance, and packaging. Send your specifications and destination port/zip code for an accurate quote.

2) Which alloy is best for cookware?

Common choices are 1050/1100 for excellent formability and 8011 for stable cookware performance. For higher strength needs, 3003 is also widely used.

3) What temper should I choose for deep drawing?

Most deep drawing applications use O temper (annealed) for maximum ductility and reduced cracking.

4) Can you supply custom diameters and thicknesses?

Yes. We support custom cutting/blanking based on your drawing or target diameter range and thickness.

5) How do you ensure quality?

We perform dimensional checks, surface inspection, and can provide material certificates. Batch identification and traceability are available.

6) What is your MOQ and lead time?

MOQ and lead time depend on the alloy and size. Many common specs can be arranged quickly; custom specs may require additional production time.

Request a Quote

To get the best aluminium circle price per kg, please share:

- Alloy (1050/1100/3003/8011)

- Temper (O/H12/H14)

- Thickness and diameter

- Quantity (kg or pieces)

- Application (cookware, lighting, stamping, deep drawing)

- Delivery location (port or full address)

We will recommend the most cost-effective grade and provide a competitive, production-ready quotation.