Aluminium Plate Boats

2026-01-12 17:20:34

Brief Introduction

Aluminium plate boats are built for real-world water conditionssalt spray, impacts, heavy loads, and frequent trailering. Choosing the right marine aluminum plate is the difference between a hull that stays straight and corrosion-free for years and one that demands constant repair.

Our aluminium plates for boat building are designed for excellent corrosion resistance, strong weld performance, and weight reduction, making them ideal for fishing boats, workboats, patrol boats, pontoons, and custom welded hull projects.

Looking for true boat-grade materials? Explore our dedicated Marine grade aluminum plate options for hulls, bottoms, decks, and structural parts.

Key Parameters (Typical Specification)

Note: Final supply can be customized to your drawing, boat type, and fabrication process.

Material / Alloy Options

- Marine-grade alloys (recommended): 5083 / 5086 / 5454 / 5754

- General fabrication options: 5052

Temper (Common)

- H111 / H112 / H116 / H32 (depending on alloy and use case)

Thickness Range (Typical Boat Plate)

- 2mm30mm (common hull plating often 3mm8mm; bottoms may be thicker)

Standard Sizes

- Width: 10002500mm

- Length: 200012000mm

- Custom cutting supported

Surface & Quality

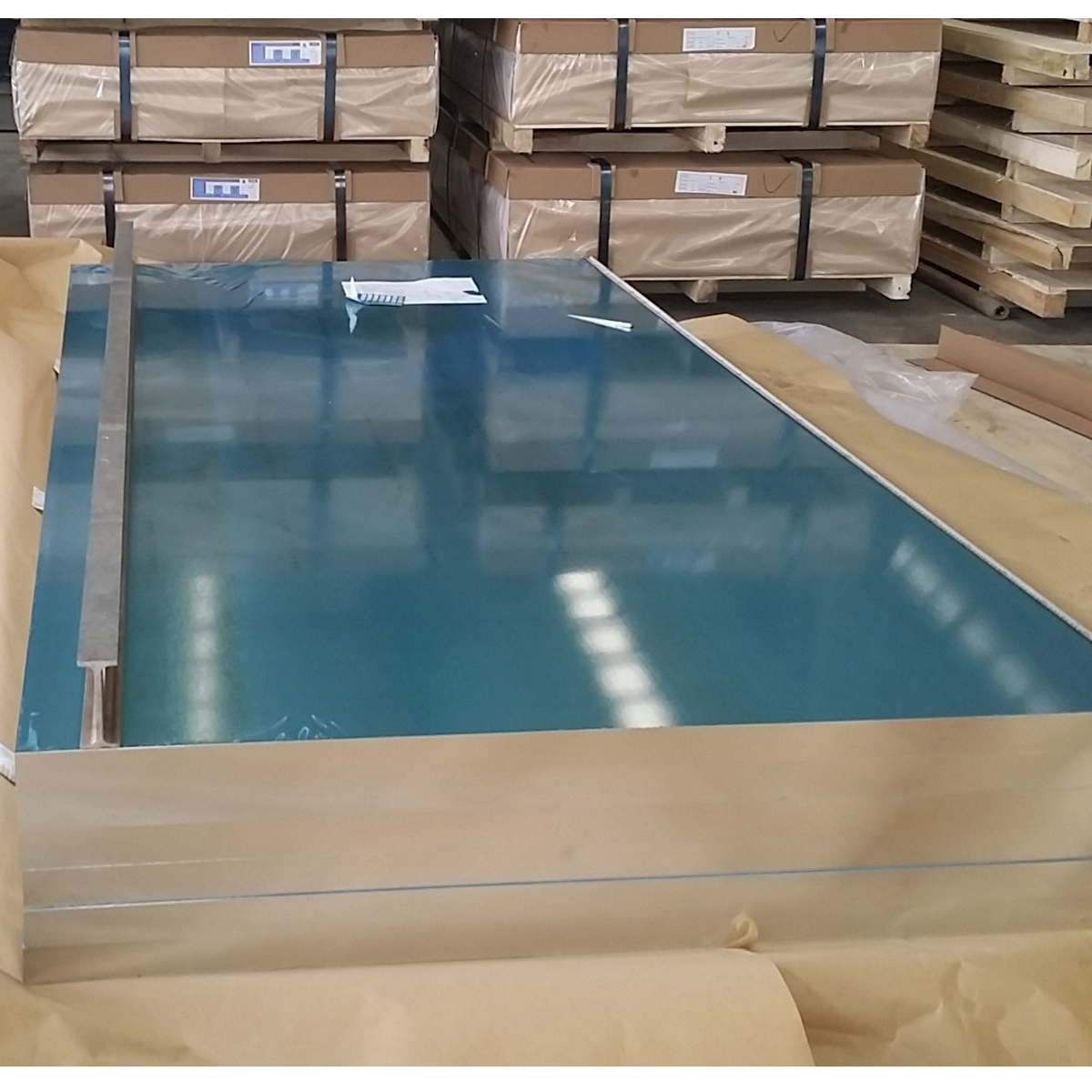

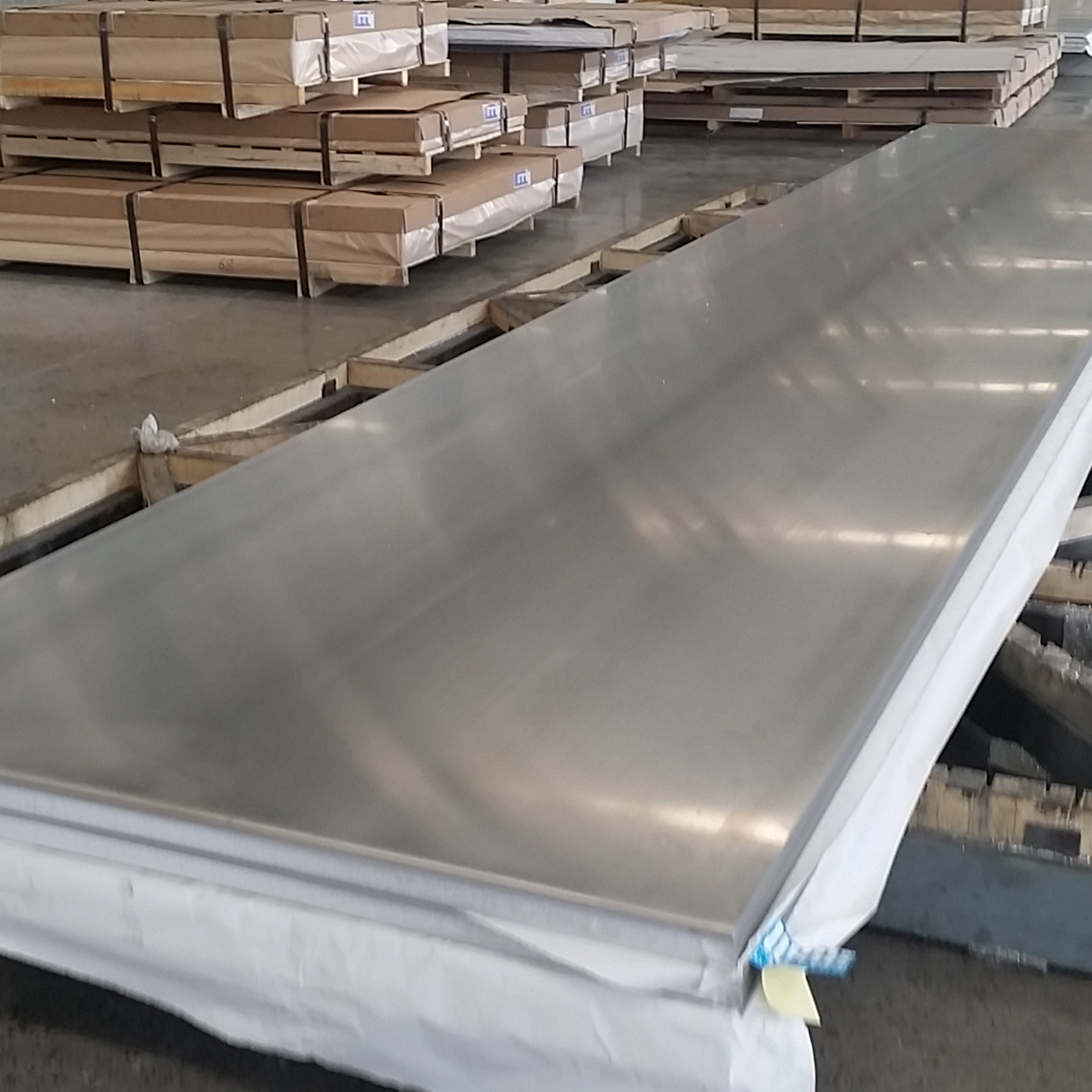

- Mill finish / brushed (optional)

- Film protection available

- Flatness control for easier welding and forming

Processing Support

- CNC cutting, shear cutting

- Bending/forming suggestions

- Welding guidance for marine alloys

Purpose & Applications

Aluminium plate boats material is widely used in:

- Boat hull plating (bottom & side shell)

- Deck and cabin panels

- Bulkheads, ribs, frames, stringers

- Transoms and reinforced load zones

- Fuel tanks and marine enclosures (alloy-dependent)

- Ramps, pontoons, floating platforms, landing craft

If your project needs high strength-to-weight and saltwater durability, 5083 is one of the most proven choices for welded hulls.

For a popular hull alloy reference, see our 5083 Aluminium Alloy Plate page.

Packaging & Delivery

We pack aluminium plates to arrive flat, clean, and ready for fabrication.

Standard packaging includes:

- Waterproof paper + moisture barrier

- Protective film (optional)

- Strong wooden pallet / fumigated export crate

- Steel strapping + corner protection

- Clear labeling (alloy, temper, size, heat/lot, net weight)

Shipping options:

- Sea freight (FCL/LCL)

- Truck/rail (regional)

- Custom packaging for long-length plates

Advantages of Aluminium Plate Boats (Why Builders Choose This Material)

1) Excellent Corrosion Resistance (Saltwater Ready)

Marine alloys are engineered to resist seawater corrosion, reducing maintenance and improving service life.

2) Lightweight for Better Speed & Fuel Efficiency

Lower hull weight improves acceleration, payload flexibility, and fuel economyespecially valuable for fishing and work boats.

3) Strong, Weldable, and Reliable

Boat plate alloys like 5083/5086 deliver high strength with stable welding performance, supporting long seams and structural joints.

4) Easy Fabrication & Customization

Aluminium plates are suitable for cutting, forming, and weldingideal for custom hull designs and repairs.

5) Long-Term Value

Reduced rust issues, fewer repaint cycles, and higher resale value compared with many traditional alternatives.

FAQ (Aluminium Plate Boats)

Q1: What is the best aluminum alloy for aluminium plate boats?

For welded hulls, 5083 (and 5086/5454) is commonly preferred due to its marine corrosion resistance and strength. The exact choice depends on hull design, thickness, and service environment.

Q2: What thickness aluminum plate is used for boat hulls?

It depends on boat length and load:

- Small boats: often 35mm

- Medium workboats: 58mm

- Heavy-duty bottoms or impact zones: 812mm+ We can recommend thickness based on your boat size and use.

Q3: Are these plates suitable for saltwater?

Yeswhen you select true marine-grade aluminum plate and follow correct welding and isolation practices (to reduce galvanic corrosion).

Q4: Can you supply cut-to-size plates for CNC or laser cutting?

Yes. We support custom cutting and can deliver plates sized for efficient nesting and reduced waste.

Q5: How do you prevent scratches during transport?

We use optional protective film, reinforced corners, and export-grade crating/palletizing to keep surfaces clean and flat.

Request a Quote

Send your required alloy, temper, thickness, size, quantity, and delivery port. If you have drawings, share themwell recommend the most suitable aluminium plate solution for your boat hull, deck, and structural components.